The Only Guide to Industrial Laser Cutting

The Only Guide to Industrial Laser Cutting

Blog Article

In relation to present day production, the precision and effectiveness of laser chopping technology are certainly video game-transforming. Laser reducing machines have revolutionized industries by delivering a approach to chopping elements with unparalleled accuracy. If you’ve ever marveled within the intricate designs on steel or wondered how advanced designs are produced so seamlessly, it’s generally the function of the industrial laser reducing equipment.

Allow’s get started with the basics: a laser cutter is usually a Device that uses a laser beam to cut products. This beam is exceptionally concentrated and generates higher temperatures to soften or vaporize the fabric, producing specific cuts. As opposed to common strategies, which could use mechanical blades, a laser cutter offers a amount of precision that is sort of unmatched. Picture looking to carve a fragile pattern by using a hammer—Evidently, a laser cutter is a great deal additional refined!

Industrial laser cutting will take this technological know-how to the following stage, giving methods for large-scale operations. These devices are designed to take care of significant supplies and large generation volumes, guaranteeing that even the most demanding tasks are finished with large effectiveness. Think about it as being the distinction between employing a precision knife for fragile paper crafts and a strong observed for chopping through thick Wooden.

The Of Industrial Laser Cutting

On the globe of CNC laser chopping, the “CNC” means Computer system Numerical Regulate. This technological know-how permits automated and extremely precise cuts by following electronic patterns. In the event you’ve at any time utilized a computer to draw and then viewed that drawing come to lifestyle, CNC laser chopping will work in an identical way, translating electronic types into physical cuts. It’s like aquiring a Digital designer Using the precision of the laser.

On the globe of CNC laser chopping, the “CNC” means Computer system Numerical Regulate. This technological know-how permits automated and extremely precise cuts by following electronic patterns. In the event you’ve at any time utilized a computer to draw and then viewed that drawing come to lifestyle, CNC laser chopping will work in an identical way, translating electronic types into physical cuts. It’s like aquiring a Digital designer Using the precision of the laser.Rumored Buzz on Laser Cutting Systems

Precision laser slicing is just not nearly producing cuts; it’s about creating them correct every single time. The laser is usually altered to accomplish diverse depths and widths, making certain that every Slash is precisely in which it has to be. This really is crucial for purposes wherever even a slight deviation may lead to substantial challenges. Imagine it like a surgeon’s scalpel, where precision is not simply crucial but absolutely important.

Precision laser slicing is just not nearly producing cuts; it’s about creating them correct every single time. The laser is usually altered to accomplish diverse depths and widths, making certain that every Slash is precisely in which it has to be. This really is crucial for purposes wherever even a slight deviation may lead to substantial challenges. Imagine it like a surgeon’s scalpel, where precision is not simply crucial but absolutely important.Laser reducing equipment is available in different forms, Just about every tailor-made to unique demands. Whether or not You will need a tiny desktop product for pastime jobs or an enormous industrial equipment for factory use, there’s a laser chopping Answer to choose from for you personally. These equipment differ in electric power, speed, and capabilities, so it’s important to select the suitable 1 for your personal specific software.

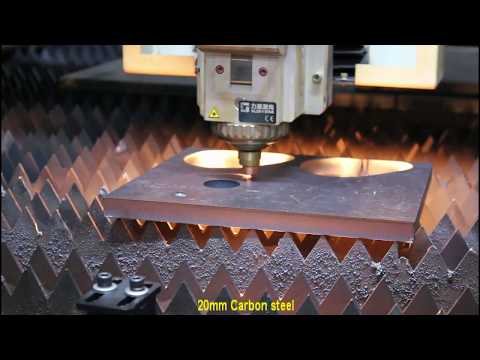

Sheet metallic laser cutters really are a Specific category of laser reducing devices built specifically for reducing metallic sheets. They are broadly Utilized in industries starting from automotive to aerospace due to their capability to take care of steel with precision and velocity. Picture a sheet of metal just like a blank canvas, plus the laser cutter given that the artist who produces sophisticated and exquisite styles with remarkable accuracy.

Laser cutting companies are A different significant element of this technology. Not Everybody wants to take a position in their own personal laser slicing device, particularly if they only need to have occasional cuts or absence the Place for these devices. Lots of providers give laser chopping products and services in which you can send out your models and also have them Lower with large precision. It’s like outsourcing your artwork to a skilled Skilled.

Laser cutting systems combine several parts to deliver the desired results. From the laser resource to your slicing bed, and also the control program, each individual Component of the program functions alongside one another to be certain a flawless operation. It’s a bit similar to a symphony orchestra, in which Every musician has a selected position, and only by Operating alongside one another do they develop a harmonious efficiency.

When it comes to laser slicing technologies, the evolution has long been quick and impressive. To begin with utilized predominantly for reducing metals, these equipment now deal with a wide array of supplies together with plastics, wood, and in many cases fabrics. This versatility would make laser cutting technological innovation a important Instrument in plenty of industries. Envision using a Swiss Military knife that may take care of nearly any substance—This is certainly what modern laser reducing know-how offers.

The accuracy of laser reducing equipment is actually remarkable. They're able to Lower supplies to within just microns of your intended layout, guaranteeing that even one of the most intricate facts are preserved. This level of precision is particularly useful in industries the place specific measurements are important. Visualize it given that the distinction between a personalized suit and off-the-rack apparel—the suit is simply perfect when.

Our Laser Cutting Technology Ideas

A different advantage of laser slicing technological innovation is its efficiency. Compared with standard chopping techniques That may require a number of steps or resources, laser slicing often completes the activity in a single go. This don't just accelerates creation but will also minimizes substance squander. It’s like having a large-pace coach that gets you for your spot immediately and efficiently without any avoidable stops.From the context of industrial purposes, the robustness of laser chopping machines is essential. These machines are developed to endure the calls for of ongoing Procedure, generally functioning 24/seven in high-volume settings. Their durability ensures constant functionality and dependability, and that is important for retaining generation schedules. It’s like using a weighty-obligation truck that reliably delivers items find out day following working day.

One of the extraordinary components of laser chopping is its capacity to make clear and precise edges. This minimizes the necessity for article-processing, visit the page including sanding or ending, which may be time-consuming and costly. The end result is often a easy, finished product That always calls for minimum additional do the job. Think about finishing a craft project without glue spills or rough edges—it’s that clean up!